FULL STEEL SILO SOLUTION

Application Fields

Fax: 86-371-6871 6761

Email:tanjie@spiral-silo.com

kingreal2004@gmail.com

Address: NO1, Renmin Road, Anyang City 455000, Henan Province, China PR

HOME >> PRODUCTS >> LIPP STEEL STORAGE SILO >> Fly Ash Storage Silo

*Widely used in the storage of cement industry*

*The spiral steel silo characteristics lie in:*

1 Good overall performance , long service life: spiral seaming edge five times the parent metal thickness, which greatly strengthens the silos` body resistance to load capacity;its stability and strength service life are better than that of other steel silos.

2 Good air-tightness,extensive usage: this seaming by special equipment bending forming , sealing performance is especially good; can be used in granular, powder, grain storage ; avoid external humidity influence in inside materials, and at the same time can satisfy the insecticidal, fumigation etc process requirement, and can also be used to store liquid objects.

3 Short construction period, low cost: the silo body weight is

equivalent to 1/6 of concrete silo with same volume , which greatly

reduce the basic cost; at the same time extremely short construction

period (1000 tons of silo, need only about five days time)

4 Small floor space, easy management:the spiral steel silo is better

than that of other silos also lies in its height and diameter,which can

be in great range choice and adaptation,e.g. granary spacing can be

small to 50 cm.

*Technical advantages of spiral steel silo:*

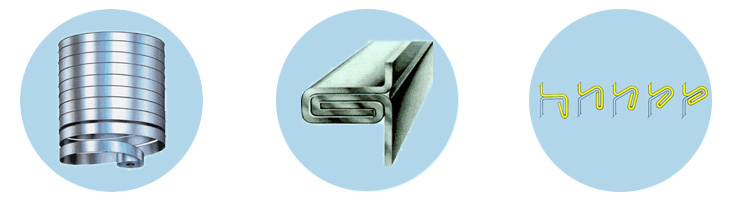

Our company adopts advanced west Germany silo construction technology,and building method is unique.While constructing, first feed 495 mm wide coil sheet by decoiling machine into bending machine bending, seaming, and then through the forming machine rolling into needed geometric shape, around the silo lateral forming a 30-40 mm wide, encircling spiral protruding strip on the structure playing the role of strengthening silo. For two different kinds of materials, silo construction equipment also can realize double bending processing.

The silo is site operation, silo top is ground installation, and no need

of scaffolding and other auxiliary facilities. Silo construction

equipment work at the speed of 3-5 m/min of forming and bending,so the

construction period is very short. Silo construction equipment only need

a truck can be delivered to site,so the transport costs is quite low.

Silo is made of thin plate, with only the equivalent of the capacity of cement bin rebar weight, so the construction cost is rather low.

*The theory of spriral steel bending*