FULL STEEL SILO SOLUTION

Application Fields

Fax: 86-371-6871 6761

Email:tanjie@spiral-silo.com

kingreal2004@gmail.com

Address: NO1, Renmin Road, Anyang City 455000, Henan Province, China PR

HOME >> PRODUCTS >> LIPP STEEL STORAGE SILO >> Construction Process of Lipp Steel Storage Silo

The main equipments for slio making machine:

For construct the lipp steel storage silos, we need a lipp silo forming machine group which including Decoiling machine, bending machine, forming machine,frames&supports,

electrical control panels.

The main current equipments are mainly SM30 lipp silo forming machine and SM40 type lipp silo making machine two specifications:SM30 steel silo forming machine is suitable for silo diameter range 3 ~ 10 meters; SM40 silo making machine is suitable for silo diameter range 6 ~ 25 meters.

Steel silo production is divided into all steel structue silo and cement foundation silo,and

all steel production base, in the foundation choice near a flat surface (had

better hardening ground).

This paper mainly introduces the whole steel based steel silo

production process.

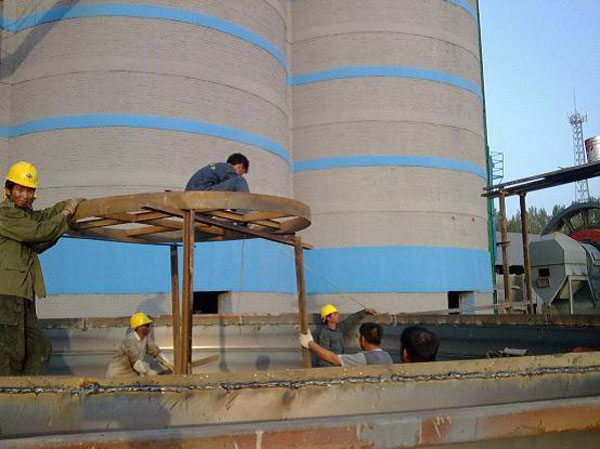

ONE、Choose flat ground to silo body diameter building steel silo

production platform, including building steel frame, steel column,

connection forming machine, etc. A finished platform is as follows:

Among them, the decoiling machine and bending machine are located silo body diameter circumferential inside, forming machine is located in the periphery.After debugging to normal,start equipments, and coil sheet through the bending machine to fluctuation periphery for bending, through the forming machine to seam.

TWO、Close the equipments when the volume to the second lap,cut the silo

top in accordance with level,weld the down ring,place rise ring in silo

body within the circle, with level and tape for measurement.

(along the horizontal cutting edge on the first lap, make its on the same horizontal plane)

(use tape, level measurement to make sure rise ring is in a center of

circle)

THREE、Welding silo top purline between rise and dow ring.

(welding purline in accordance with layout design)

FOUR、Welding silo top cover plate

FIVE、Welding silo top guardrail and making manhole.

SIX、Painting the silo top (this step is mainly used in the black plate )

Finished steel silo roof:

SEVEN、Reopen the decoiling machine to roll up.

In this process coordinate with painting and welding reinforcing steel bar and the inside ladder.

EIGHT、To achieve the intended design height

To silo bottom for horizontal cutting,and lift silo body with crane to structure platform.

*Manufacture process in silo internal structure:*

ONE、Coil sheet into bending machine

Bended edge comes out from another end.

TWO、From bending machine into forming machine for seam forming

THREE、The silo inside welded reinforcing steel bar

FOUR、The silo inside ladder