FULL STEEL SILO SOLUTION

Application Fields

Fax: 86-371-6871 6761

Email:tanjie@spiral-silo.com

kingreal2004@gmail.com

Address: NO1, Renmin Road, Anyang City 455000, Henan Province, China PR

Construction Process of Spiral Steel Silo

The production of silos that BAIRONG offers on the market is absolutely concurrent to all up to date applied building systems. This silo type is has a number of advantages among which we underline:

*silos are built on the spot, of steel strips,

*cells diameters range from 2,6 to 20 meters

*the cells application is universal for grains, combustive fluids, and other chemicals in liquid state, granular and pulverized state

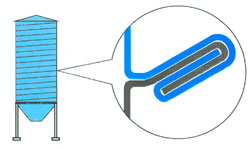

*the principle of spiral of folding: folding of the adjoining edges connects the sheets and seals them

*for aggressive environments, the silo is built of two strips. The outside one is the weight carrying element, while the inside one is the resistant one to silo's aggressive contents.

Helix / Spiral Steel Silo loading is performed using an elevator. The substance is injecting into the cells.

Cells unloading relies on gravity. Transporter loading takes part, then the substance is further carried to lines. A lid is installed on cells exit. Installing a vibro extractor is a good option to consider. The vibro extractor's role is to speed up the unloading of slow running substances.

The transport equipment's loading and unloading capacity can be 30, 60 and 100 tons per hour.

PHASE I: |

|||

PHASE II: |

|||

PHASE III: |

|||

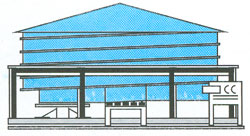

PHASE IV: |

|||

PHASE V: |

|||

DETAIL: |